Anodised Aluminium Front Panels: The Ideal Solution for High-Stress Electronic Applications

In today’s fast-paced world, technology and devices play a crucial role in various industries and applications. From industrial automation to high-end consumer electronics, the need for small, durable, and high-quality front panels is becoming increasingly important. These front panels not only protect the delicate internal components of devices but also contribute to their overall aesthetics, ensuring that they function optimally and look great.

Selecting the suitable front panel material is essential to ensure the longevity and performance of a device. Many industries face unique challenges, such as exposure to harsh chemicals, extreme temperatures, moisture, and corrosive environments, which demand front panels that can withstand these conditions while maintaining their appearance and functionality.

Resilient front panels are vital for electronic systems operating in high-stress situations or extreme environmental conditions, as they safeguard the equipment from potential damage and ensure its reliability. Aesthetic appeal, durability, and resistance to various environmental factors are also crucial for premium electronic devices, as they cater to discerning customers seeking high performance and an attractive design.

Addressing these diverse challenges across multiple industries may seem like a daunting task. However, the unique properties of anodised aluminium front panels make them the ideal solution to meet the demands of these varied applications. With temperature and solvent resistance, unparalleled durability, and customisable aesthetic features, anodised aluminium panels provide a versatile and reliable option that caters to the specific needs of each industry, ensuring optimal performance and longevity of devices and equipment.

As manufacturers of front panels, we recognise the importance of offering unique solutions that cater to the diverse needs of various industries. Anodised aluminium, with its exceptional durability and high-performance features, is our material of choice, setting a new standard for quality and innovation in the field.

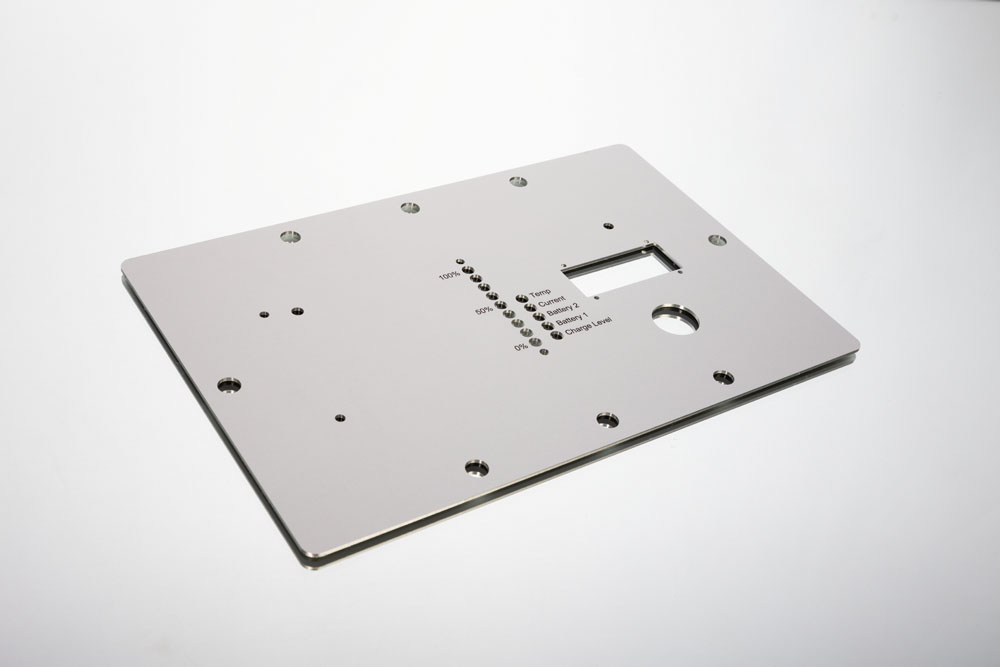

Boasting an array of benefits, such as waterproofing, acetone resistance, fire resistance, high-temperature endurance, and corrosion resistance, anodised aluminium panels are ideal for demanding applications. Additionally, these front panels can be fully customised with high-quality, full-colour printing, ensuring they not only provide robust protection but also enhance the overall aesthetics of any device.

Anodised aluminium panels owe their exceptional durability to a unique electrochemical process that increases the thickness of the aluminium oxide layer on the surface. This layer not only fortifies the panel against wear and tear but also provides a robust barrier against harsh chemicals, moisture, and extreme temperatures.

Moreover, anodised aluminium is environmentally friendly and recyclable, making it an ideal choice for industries looking to minimise their ecological footprint.

Another critical advantage of anodised aluminium panels is their ability to maintain their vibrant colours and pristine appearance for an extended period. Thanks to the advanced printing technology used in creating these custom front panels, the colours are infused into the anodised layer, ensuring that they won’t peel, fade, or chip over time. This makes anodised aluminium an excellent option for applications that require a combination of durability, functionality, and visual appeal.

Electronic devices and equipment face many challenges impacting performance, longevity, and reliability. For instance, devices operating in environments with high temperatures, dust, and moisture require robust protection to maintain their functionality and prevent damage to delicate internal components. Equipment exposed to harsh chemicals, solvents, and extreme heat must withstand these conditions to preserve accuracy and reliability in data collection and analysis.

Durability and corrosion resistance are essential for devices subjected to frequent sterilisation and rigorous cleaning procedures to prevent bacterial contamination and ensure compliance with stringent hygiene standards. Protection from harsh weather conditions and corrosive environments is crucial for maintaining the integrity of electronic systems, navigation equipment, and communication devices in various settings.

If you’re interested in learning more about our anodised aluminium panels and how they can elevate the functionality of your electronic devices, please don’t hesitate to contact us today for a custom quote!