MeFace Ltd is a UK-based manufacturer of anodised aluminium front panels, nameplates and labels.

We stay up-to-date with industry trends to provide our customers with the best and most innovative products.

Cutting Aluminium Front Panel with statistics

Research and Development: Safe, Smart and Effective Solutions

By researching and developing safer, smarter and more cost-effective production methods, we can deliver the highest-quality products faster and reasonably priced. At the same time, our experienced team ensures our clients always enjoy the absolute best in customer service.

This dedication to quality craftsmanship and outstanding customer service has helped us maintain strong relationships with prestigious clients in many industries.

Today, we are honoured to have clients in the UK, the US, and across continental Europe who trust us with their new projects and repeat orders.

Digital Printing Trend

Digital Printing: A Process with Endless Potential

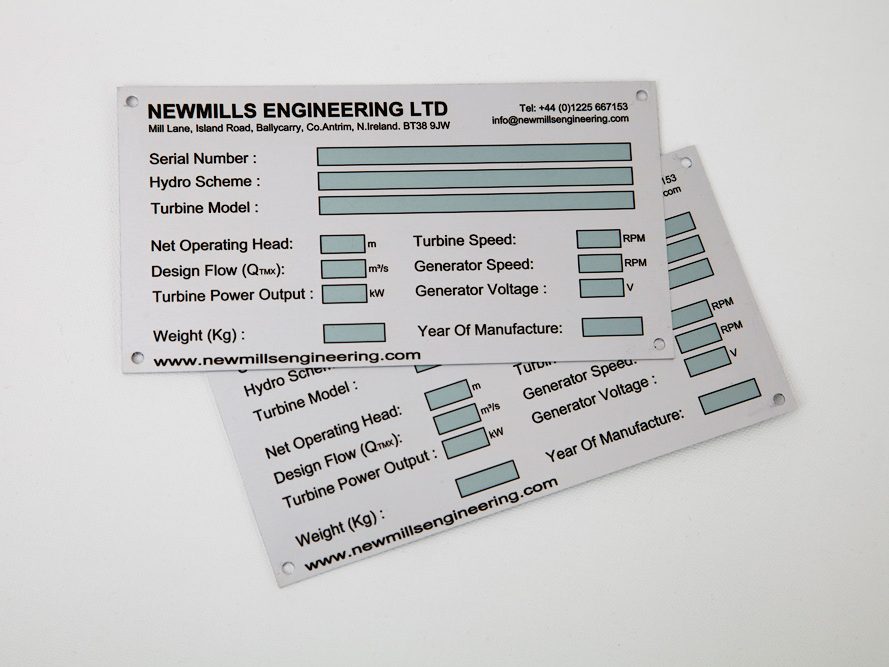

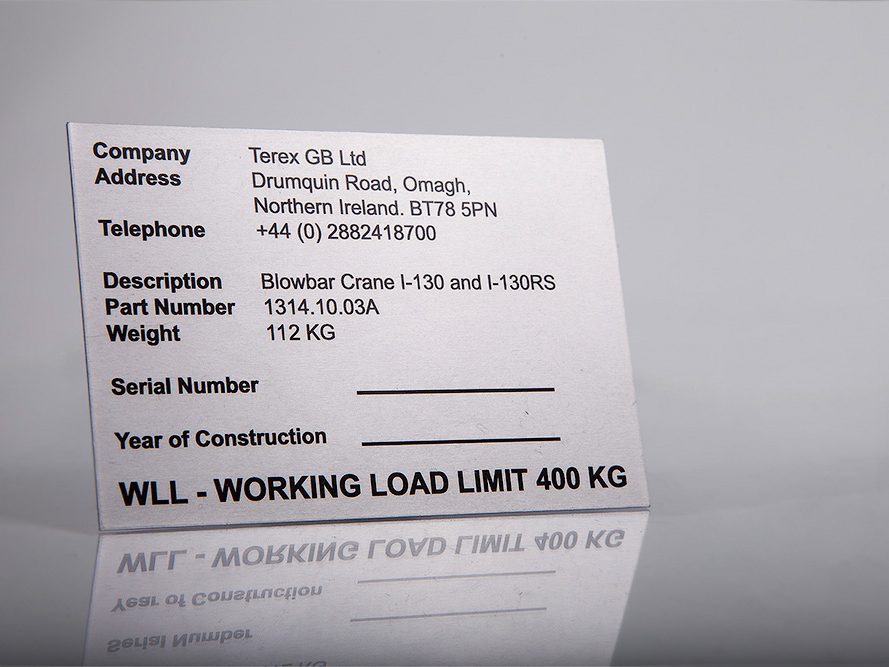

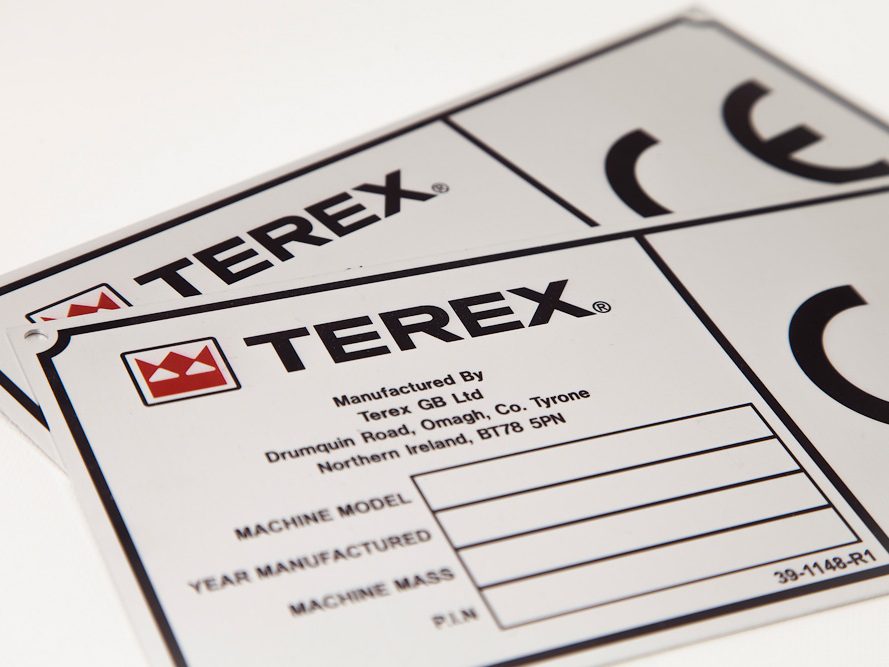

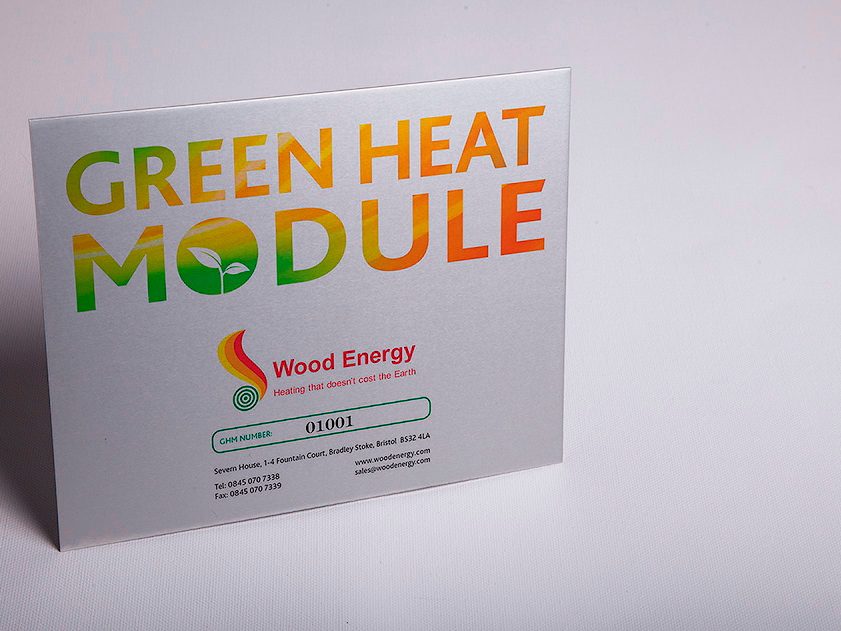

Our in-house industrial printers are designed specifically for anodised aluminium sub-surface digital printing. With a working area of 1000mm x 2000mm, a heated vacuum table, and premium inks, we can print full-colour graphics with a photo-quality resolution of 2880 x 1440 dpi onto a wide range of metal sheets (0.3mm, 0.5mm, 1mm, 1.5mm, 2mm, 2.5mm, 3mm, 3.5mm and 4mm or more).

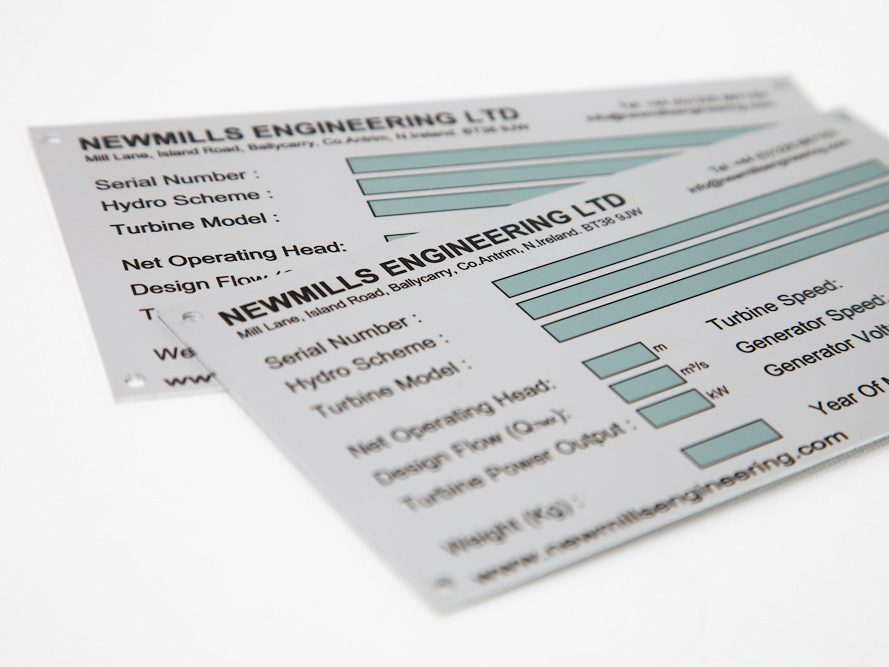

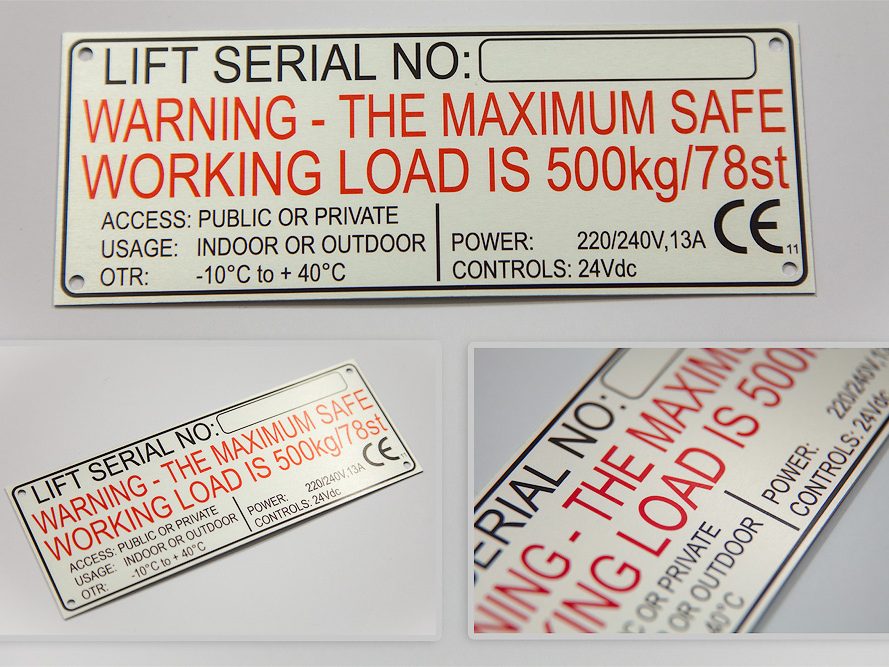

Digital printing also enables us to make bespoke, extra-durable anodised aluminium front panels, labels, nameplates, data plates, rating plates, VIN plates, badges, key tags, and other product identification plates with unique or sequential serial numbers.

Vector Artwork: The Bridge between Printer and Cutter

We can use vector artwork in any file format (.eps, .ai, ,dxf, .swg, .pdf, and more) to help us create toolpaths for machining.

If you use Front Panel Designer software to draw your front panels, we will work with your saved .fpd files! Ask us for an independent quote to maximise cost savings when you provide your files.

Selection of Tools for Aluminium Front Panel Production

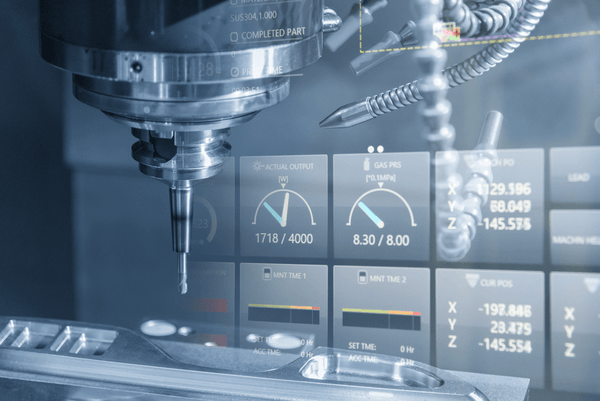

Digital Cutting: Computer Numerical Control (CNC) Milling Machines

From printed sheets to finished products with no delay!

Once the printing process is complete, we position each printed sheet within the working area of one of our CNC milling machines and let that machine cut everything precisely to the required specifications.

To ensure we always exceed customer expectations, we use a variety of highly-specialised tools, from our tiny 1mm-diameter end mills to burrs for countersink holes and huge drills.

No project is ever too big, small, or complicated for our highly skilled team. Whether you need a one-off prototype or a large quantity of your finished product, our enthusiastic team is ready to help you at every step of the production process, from design to delivery.

To find out more about Meface’s printing and manufacturing capabilities, please use LiveChat, email us at sales@meface.co.uk, or request a quote online today.